Single Ferrule Design - DIN 2353

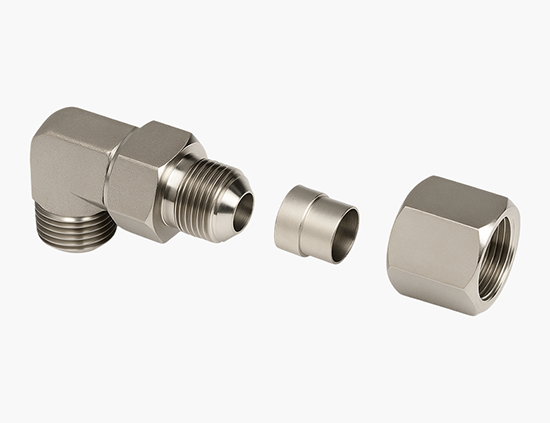

These Single Ferrule Bite Type Fittings are the most widely used bite type fittings in the world. These Single Ferrule Bite Type Fittings are flareless bite type metric fittings that consists of a body, progressive ring (ferrule) and nut. On assembly, two cutting edges of the ferrule “bite” into the outer surface of the tube ensuring the necessary holding power for high operating pressures.

Features

These Single Ferrule Bite Type fittings and accessories (Three Series)are manufactured in accordance with DIN 2353 for fluid application.

These Single Ferrule Bite Type fittings and accessories (Three Series)are manufactured in accordance with DIN 2353 for fluid application. The three components of Single Ferrule Bite Type Fittings are designed to produce a strong, reliable, leak-free joint upon proper assembly.

The three components of Single Ferrule Bite Type Fittings are designed to produce a strong, reliable, leak-free joint upon proper assembly. Couplings are best suited for steel, copper or stainless steel tubes where brazing, soldering, welding, flaring or threading is not possible or permissible.

Couplings are best suited for steel, copper or stainless steel tubes where brazing, soldering, welding, flaring or threading is not possible or permissible.

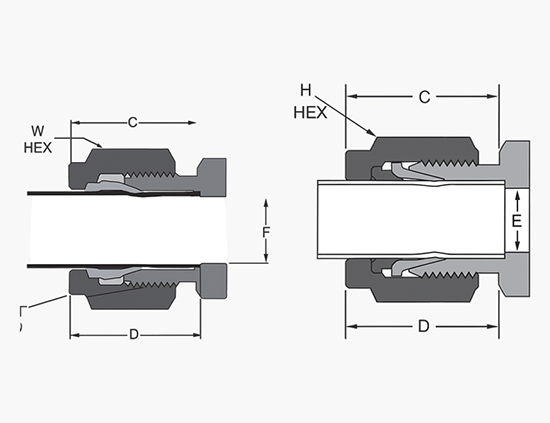

Working Principle

Single Ferrule Bite Type Fitting is a flare less three-piece design fitting comprising of a Socket body having a precision conical seat, a one-piece precision machined hardened Progressive Ring (ferrule) and a Coupling Nut. When the Coupling Nut is progressively tightened it makes the Progressive Ring to move on to the tube which subsequently makes two bites into the outside diameter of the pipe, thereby forming a visible collar of material at A, ensuring a strong, reliable, high degree of safety and permanent sealing due to the outstanding construction & design of our progressive ring. A second seal point at B is also created between the now bowed ferrule and the fitting body seat. The progressive ring in its dismantled state can be turned around while still on the tube.

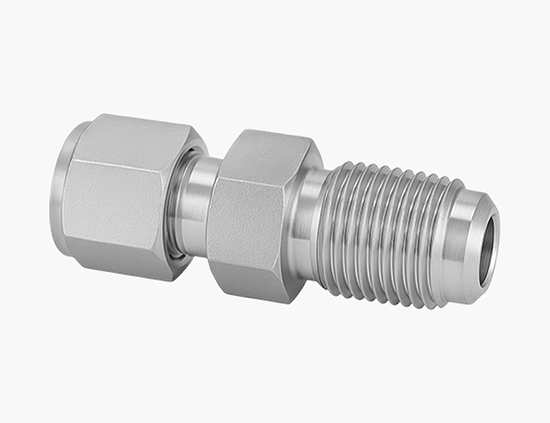

Twin Ferrule Bite Type Fittings

Twin Ferrule Bite Type Fittings are sold completely assembled and ready for immediate use. Simply insert the tube as illustrated until it bottoms in the fitting body. (If the fitting is dis-assembled, note that the small tapered end of the ferrule (s) go into the fittings body).

Method

Simply place the nut on the thread and rotate. Tighten the nut using wrench with 1 - 1/4 turns as indicated below. Hold the fitting body with a second wrench to prevent it from turning. It is helpful to mark the nut to facilitate counting the number of turns For maximum number of remakes, mark the fitting and nut before disassembly. Before retightening, make sure the assembly has been inserted into the fitting until the ferrule seats in the fitting. Retighten the nut by hand. Rotate the nut with a wrench to the orginal position as indicated by the previous marks lining up. (A noticeable increase in mechanical resistance will be felt indicating the ferrule is being re - sprung into sealing posistion. Only after several remakes will it become necessary to advance the nut slightly past the original position. This advance (indicated by B) need only be 100 - 200(less than 1/3 of a hex flat).

Tubing Ordering Suggestions

Tubing for use with Ve - Lock instrument fitting must be carefully ordered to insure adequate quality for good performance. Each purchase order must specify the material nominal outside diameter, and wall thickness. Ordering to ASTM specifications insure that the tubing will be dimensionally, physically and chemically within strict limits. Also more stringent requirements may be added by the user. All tubing should be completely free of scratches and suitable for bending.

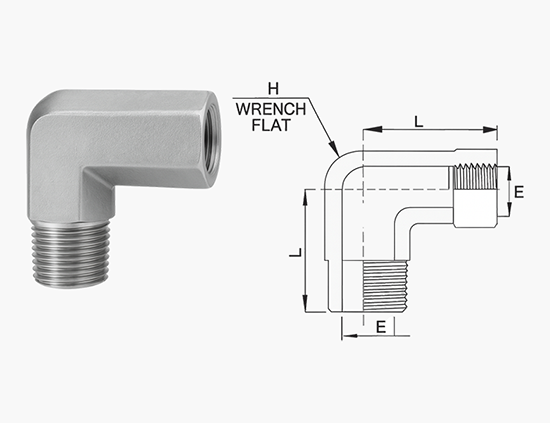

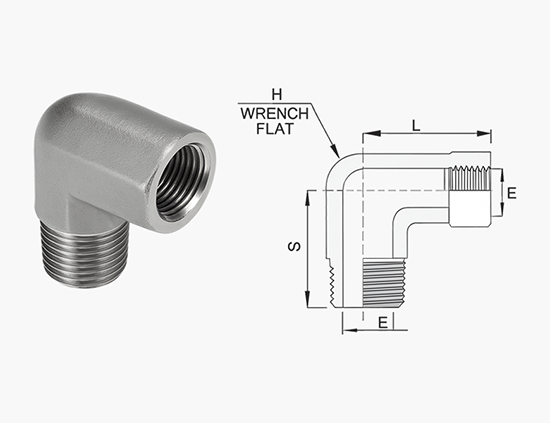

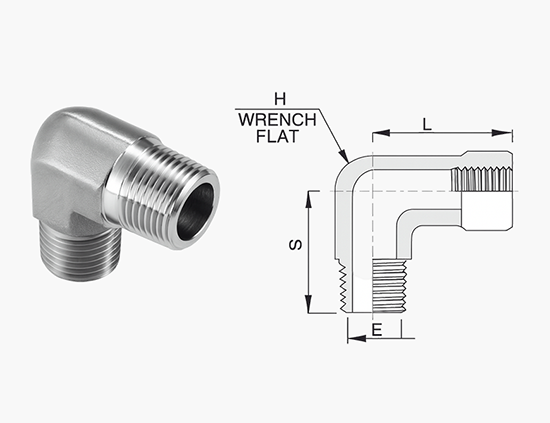

Instrument Thread Fittings

Features

Precision pipe fittings for instrumentation and process control.

Precision pipe fittings for instrumentation and process control. Fine Threads constructed to ensure leak-free & reliable systems.

Fine Threads constructed to ensure leak-free & reliable systems. Male treads are protected with plastic cap Tube Fittings, Instrument Thread Fittings.

Male treads are protected with plastic cap Tube Fittings, Instrument Thread Fittings. Various materials including SS316, Brass and Carbon steel.

Various materials including SS316, Brass and Carbon steel. Many choice of connection and configurations are available.

Many choice of connection and configurations are available. PTFE tape applied to male threads limits the maximum temperature to + 4500 F (2320 C).

PTFE tape applied to male threads limits the maximum temperature to + 4500 F (2320 C).

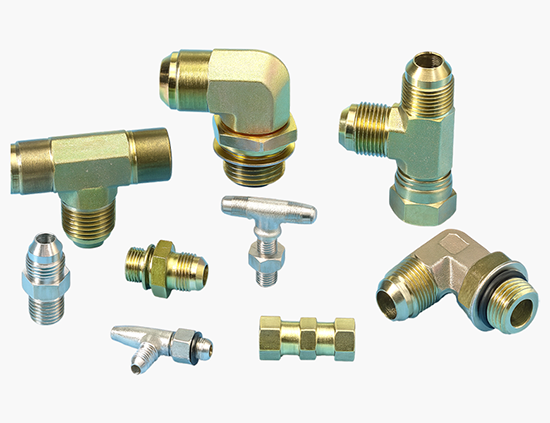

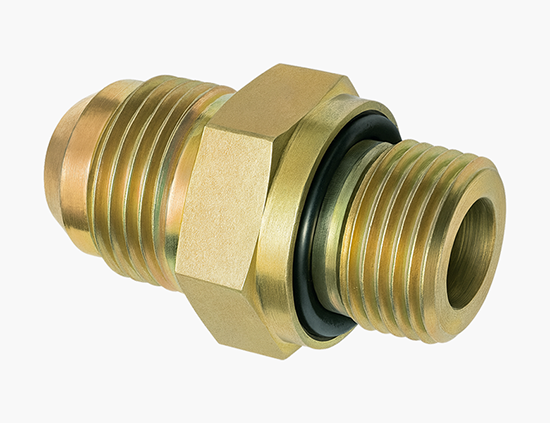

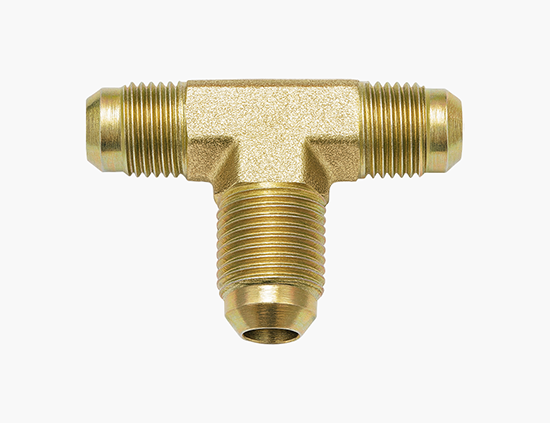

JIC 37° Flare Fittings

Ve-Lock represents the JIC 37° Flare Fitting concept since year 1994 and the design has since gained worldwide acceptance due to its many inherent features and customer benefits. Today, the JIC 37° Flare Fitting is the most widely used fitting in the world. Its appeal is in its simplicity, compact design, ease of assembly, reliability (single seal), material availability, adaptability to inch or metric tube, worldwide availability and acceptance. Further helping its acceptance is its widespread use as a hose Adaptor.

Even though JIC 37° Flare Fittings are generally considered to be 3000 psi fittings, Ve-Lock's capabilities range from 9000 psi for 1/4" size to 2000 psi for 2" size. Currently,it is used in virtually every application that uses fluid power for motion control.

Features

Specially suited for thin and medium wall thickness tube.

Specially suited for thin and medium wall thickness tube. Designed to meet the strict requirements of SAE J514 and ISO 8434-2 industry standards.

Designed to meet the strict requirements of SAE J514 and ISO 8434-2 industry standards.

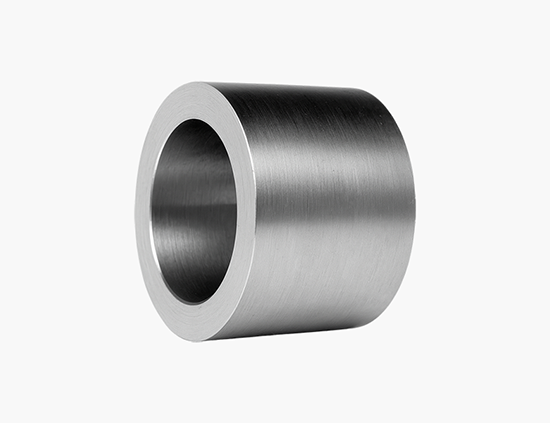

Socket Weld Tube Fittings

Ve-Lock, socket weld tube fittings are suitable for application in diverse industries like engineering, construction etc. Available in different shapes and sizes, these durable Socket weld fittings can withstand high temperature and pressure.

Features

The fittings weld seamlessly with respective pipe / tube as per ASME standards.

The fittings weld seamlessly with respective pipe / tube as per ASME standards. Designed as per ASME standards (3000 lbs / 6000 lbs).

Designed as per ASME standards (3000 lbs / 6000 lbs). Available in mild and stainless steel construction.

Available in mild and stainless steel construction. Standard size ranging from 1/2"NB up to 12"NB.

Standard size ranging from 1/2"NB up to 12"NB. Available in 3000 PSI and 6000 PSI series.

Available in 3000 PSI and 6000 PSI series.